- Details

- Category: Quality Control

Direction of the cause and solution for common conveyor belt problems

| What's the problem? | Why it happens? | The solution |

| 1. Belt edge wear and broken excessively | 1) Off centre loading | Adjust chute to place load on centre of belt and discharge material in direction of belt moving. |

| 2) Material Spillage and cumulation | Improve loading and conveying conditions, install cleaning devices, improve maintenance. | |

| 3) Bowed belt | For new belt this condition should disappear soon, otherwise the belt must be straightened or replaced. In the meanwhile, should check storage and handling situation. | |

| 4) Belt hitting structure | Install training idlers on carrying and return sides. | |

| 5) Belt too rigid for adequate troughing | Install a more flexible belt. | |

| 2. Stripping of cover | 1) Impact of materials on belt | Reduce impact by improving chute design, install impact idlers or impact bed. |

| 2) Skirt board improperly adjusted or of wrong martial | Adjust Skirt Board support to minimum 25 mm between metal and belt with gap increasing in direction of belt travel. Kindly note: use skirt board rubber (not old belt). | |

| 3. Severe pulley cover wear | 1) Material trapped between belt and pulley | Install scraper on return run ahead of tail pulley. |

| 2) Spillage on drive pulley | Increase tension, lag drive pulley, increase arc of contact. | |

| 3) Sticking Idlers. | Free idlers and improve maintenance. | |

| 4. Cover harden or crack | 1) Heat or chemical use condition | Use belt designed for specific condition. |

| 2) Improper storage or handling | Refer proper storage and handling instructions. | |

| 5. Cover softening or swells in spots | 1) Contamination by spilled grease, overlubrication of idlers | Improve house-keeping, reduce quantity of grease used, check grease seals. |

| 6. Cover bubbles | 1) Cover cuts or very small punctures | Make spot repair with vulcanizer or self curing repair material. |

| 7. Short breaks in carcass parallel to belt edge, start break in carcass | 1) Impact of material on belt. | Reduce impact by improving chute design, install impact idlers or impact bed. |

| 2) Material trapped between belt and pulley | Install scraper on return run ahead of tail pulley. | |

| 8. Transverse breaks | 1) Belt edges folding up on structure | Readjust idlers in affected area, install limit switches provide more clearance. |

| 2) Improper transition between troughed belt and terminal pulley | Adjust transition as recommended. | |

| 3) Severe convex, vertical curve. | Decrease idler spacing in curve, increase curve radius | |

| 9. Lengthways carcass break with covers intact. | 1) Belt running off centre and folding over | Use limit switches and determine reasons for belt running out. |

| 10. Belt breaks at or behind fasteners, fasteners pullout | 1) Wrong type of fastener, fasteners too tight or too loose | Use proper fasteners, set up schedule for regular fastener inspection. |

| 2)Fastener plates too long for pulley size | Replace with smaller fasteners, increase pulley size. | |

| 3) Tension too high | Increase speed, reduce friction decrease tension by increase arc of contact. | |

| 11. Ply separation | 1) Pulley too small | Use larger diameter pulleys. |

| 2) Heat or chemical use condition | Use belt designed for specific condition. | |

| 3) Too many reverse bends | Use more flexible belt. | |

| 4) Mildew or dust penetration into carcass | Prevent cuts, arrange for immediate repairs. | |

| 12. Particular section of belt runs to one side at all points on conveyor | 1) Belt not joined squarely | Remove affected splice and re-splice. |

| What's the problem? | Why it happens? | The solution |

Broken |

1. Foreign object in drive 2. underdesigned drive 3. sharp band caused tensile cord damage |

1. shield drive 2. redesign drive 3. follow proper storage and handling procedures |

Excessive sidewall wear |

1. worn of damaged sheaves 2. Misalignment or non-rigid centers 3. Bent flange |

1. Replace of sheaves 2. Align drive or reinforce mounting 3. Straighten flange |

Crack |

1. high temperature 2. sheave diameter too small 3. slippage |

1. remove heat source 2. redesign drive 3. retension drive |

Cord Failure |

1. high temperature 2. sheave diameter too small |

1. remove heat source 2. redesign drive |

Broken |

1. Foreign object in drive 2. underdesigned drive 3. sharp band caused tensile cord damage |

1. shield drive 2. redesign drive 3. follow proper storage and handling procedures |

Wear |

1. the tension force is not enough 2. Belt is too wide |

1. make the belt fastened 2. Fit the belt with proper steps |

Crack |

1. high temperature 2. sheave diameter too small |

1. remove heat source 2. redesign drive |

Rob failure |

Wrong Equipping Belt or Driver | Make sure that Belt is fixed well |

| Belt Noise | 1. belt slip 2. misaligned sheaves 3. wrong belt type |

1. retension 2. realign sheaves 3. replace cut edge with wrapped belt |

- Details

- Category: Quality Control

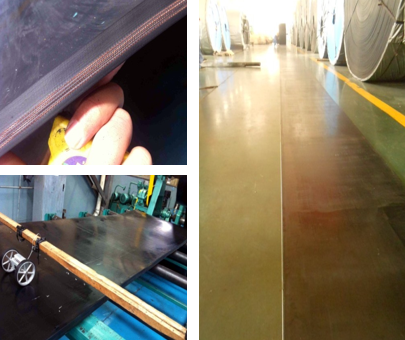

We have one professional QC team checking the surface quality for every order.

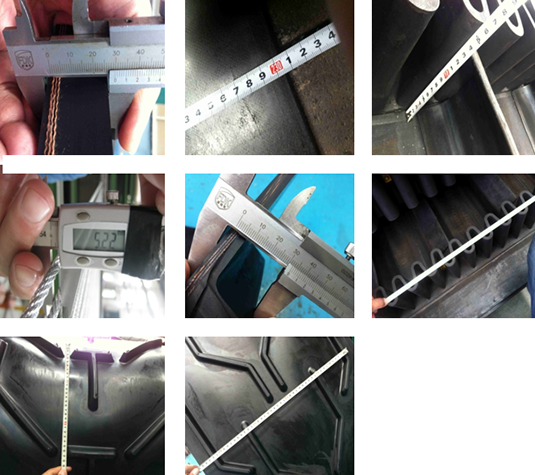

![]() Belt size checking (thickness,width,sidewall height,steel cord diameter,pitch)

Belt size checking (thickness,width,sidewall height,steel cord diameter,pitch)

![]()

Belt edge,length,straightness checking

![]()

Impact bar size & hardness checking

![]()

Steel shaft MPI and size cheking

- Details

- Category: Quality Control

Testing Lab

- We have our own testing lab double checking the inside quality.

- We make sure that every order we sent meet the customers' requirements.

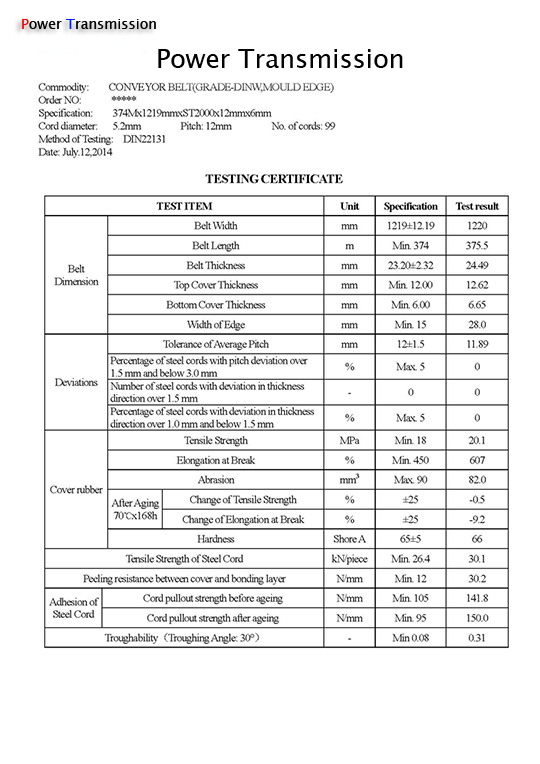

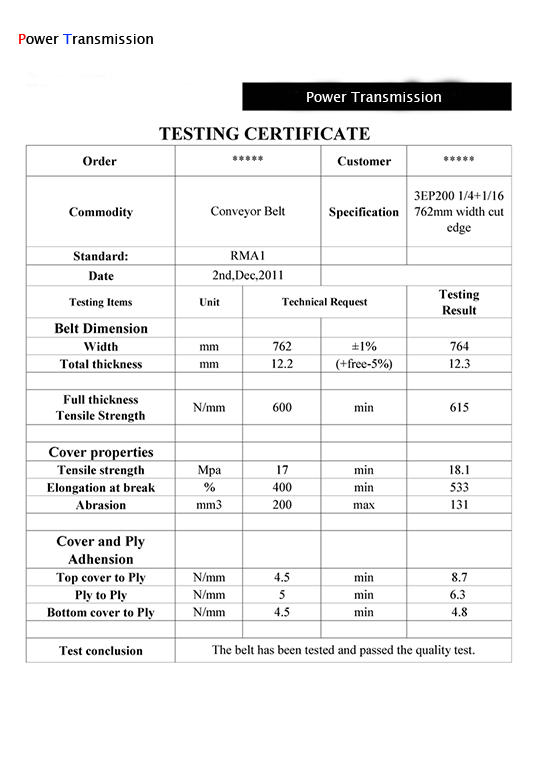

![]() Test Report

Test Report

EP belt

ST belt