Light Duty PVC belt

Light Duty PVC belt

I. Description:

- Light duty conveyor belt have a wide range, to suit almost all the Industries under roof.

- Our light duty industrial conveyor belts are manufactured with various base fabrics like polyester, nylon, cotton, etc., and surface coating with PVC/PU/PE/TPE, etc.

- These belts are available in White, Green, Black or any other color according to specific requirement, up to 3000 mm wide.

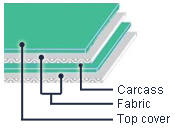

Construction:

![]()

II. Code and Abbreviations:

| Type of material | ||||||||||||

| Ply number | ||||||||||||

| Type of fabric | ||||||||||||

| Color | ||||||||||||

| Total thickness (mm/10) | ||||||||||||

| Top surface pattern | ||||||||||||

| Top cover thickness (mm/10) | ||||||||||||

| Bottom surface pattern | ||||||||||||

| Special characteristics | ||||||||||||

| C | 2 | 5 | - | G | 20 | - | S01 | 05 | / | S00 | A | |

Type of material:

| C | PVC | |||||||||||||

| U | PU (polyurethane) | |||||||||||||

| E | PE (polyethylene) | |||||||||||||

| T | TPE polyethylene (Hytrel®) | |||||||||||||

| S | Silicon | |||||||||||||

| P | polyamide | |||||||||||||

Type of fabric:

| 0 | Polyester spun, strong structure | |||||||||||||

| 1 | Polyester multifilament | |||||||||||||

| 2 | Polyester monofilament, with lateral stability, strong structure | |||||||||||||

| 3 | Polyester / Cotton | |||||||||||||

| 4 | Polyester spun | |||||||||||||

| 5 | Polyester monofilament, with lateral stability | |||||||||||||

| 6 | Cotton | |||||||||||||

| 7 | Polyester multifilament, heavy construction, with lateral stability | |||||||||||||

| 8 | Polyester multifilament, heavy construction | |||||||||||||

| M | Felt | |||||||||||||

Code of color:

| T | natural/transparent | |||||||||||||

| G | green | |||||||||||||

| W | white | |||||||||||||

| B | black | |||||||||||||

| GR | grey | |||||||||||||

| R | red | |||||||||||||

| BR | brown | |||||||||||||

| P | petrol | |||||||||||||

| BL | blue | |||||||||||||

| O | orange | |||||||||||||

Special characteristics (material):

| O | Oil resistant | |||||||||||||

| F | flame resistant | |||||||||||||

| C | Conductive(105Ω ) | |||||||||||||

Special characteristics (fabric):

| A | Anti-static carbon fiber | |||||||||||||

| D | Low noise fabric | |||||||||||||

| I | Impregnated fabric | |||||||||||||

| G | Extra rigid fabric(Latitudinal thicker) | |||||||||||||

| L | Low shrink rate fabric(Longitudinal stronger) | |||||||||||||

![]()

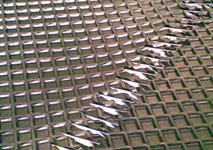

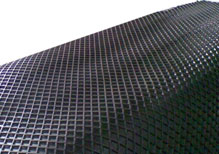

III. Surface Patterns:

S00 |

S01 smooth |

S02 matt finishing |

S03 rough matt finishing |

S04 |

S05 |

S06 |

S07 |

S08 |

S09 |

S10 |

S11 |

S12 |

S13 |

S14 |

S15 |

S16 |

S17 |

S18 |

S19 |

S20 |

S21 |

S22 |

S23 |

S24 |

S25 |

S26 |

S27 |

S28 fine fabric impression |

S29 rough fabric impression |

![]()

IV. Application:

Logistics and Airports:

We supply a wide range of Light Duty Conveyor Belts suitable for the logistics sector and airports. They are low noise, low elongation,abrasion resistant and easy to install. They are widely used in super market, warehouse, postal package, distribution centre, airport check-in area, security check etc.

The normal types are as follows:

| C25-G20-S0105/S00A |

|||||||||

| Color | Total thickness (mm) | Weight (kg/m2) | Top cover thickness (mm) | Top Coating Shore A | Working Temp. (°C) | Pull for 1% Elongation (N/mm) | Min. Pulley Dia.(mm) | Max. Width(mm) | Lateral Stability |

| G | 2 | 2.3 | 0.5 | 80 | -15/+80 | 8 | 40 | 3000 | * |

| C25-G21-S0506/S00A |

|||||||||

| Color | Total thickness (mm) | Weight (kg/m2) | Top cover thickness (mm) | Top Coating Shore A | Working Temp. (°C) | Pull for 1% Elongation (N/mm) | Min. Pulley Dia.(mm) | Max. Width(mm) | Lateral Stability |

| G | 2.1 | 2.2 | 0.6 | 80 | -15/+80 | 8 | 40 | 3000 | * |

| C21-G20-S0105/S00CA |

|||||||||

| Color | Total thickness (mm) | Weight (kg/m2) | Top cover thickness (mm) | Top Coating Shore A | Working Temp. (°C) | Pull for 1% Elongation (N/mm) | Min. Pulley Dia.(mm) | Max. Width(mm) | Lateral Stability |

| G | 2 | 2.3 | 0.5 | 70 | -15/+80 | 12 | 30 | 3000 | |

| C25-G30-S0110/S00A |

|||||||||

| Color | Total thickness (mm) | Weight (kg/m2) | Top cover thickness (mm) | Top Coating Shore A | Working Temp. (°C) | Pull for 1% Elongation (N/mm) | Min. Pulley Dia.(mm) | Max. Width(mm) | Lateral Stability |

| G | 3 | 3.3 | 1 | 80 | -15/+80 | 8 | 60 | 3000 | * |

| C22-G55-S0435/S00D |

|||||||||

| Color | Total thickness (mm) | Weight (kg/m2) | Top cover thickness (mm) | Top Coating Shore A | Working Temp. (°C) | Pull for 1% Elongation (N/mm) | Min. Pulley Dia.(mm) | Max. Width(mm) | Lateral Stability |

| G | 5.5 | 4 | 3.5 | 55 | -20/+60 | 10 | 80 | 2000 | * |

| C22-G31-S0106/S05 |

|||||||||

| Color | Total thickness (mm) | Weight (kg/m2) | Top cover thickness (mm) | Top Coating Shore A | Working Temp. (°C) | Pull for 1% Elongation (N/mm) | Min. Pulley Dia.(mm) | Max. Width(mm) | Lateral Stability |

| G | 3.1 | 3.1 | 0.6 | 80 | -15/+80 | 10 | 60 | 3000 | * |

| C32-G46-S0110/S05 |

|||||||||

| Color | Total thickness (mm) | Weight (kg/m2) | Top cover thickness (mm) | Top Coating Shore A | Working Temp. (°C) | Pull for 1% Elongation (N/mm) | Min. Pulley Dia.(mm) | Max. Width(mm) | Lateral Stability |

| G | 4.6 | 5 | 1 | 80 | -15/+80 | 15 | 100 | 3000 | * |

| C32-G38-S0110/S00A |

|||||||||

| Color | Total thickness (mm) | Weight (kg/m2) | Top cover thickness (mm) | Top Coating Shore A | Working Temp. (°C) | Pull for 1% Elongation (N/mm) | Min. Pulley Dia.(mm) | Max. Width(mm) | Lateral Stability |

| G | 3.8 | 4.1 | 1 | 80 | -15/+80 | 15 | 120 | 3000 | * |

| C21-B20-S0205/S00 |

|||||||||

| Color | Total thickness (mm) | Weight (kg/m2) | Top cover thickness (mm) | Top Coating Shore A | Working Temp. (°C) | Pull for 1% Elongation (N/mm) | Min. Pulley Dia.(mm) | Max. Width(mm) | Lateral Stability |

| B | 2 | 2.3 | 0.5 | 80 | -15/+80 | 12 | 30 | 3000 | |

| C25-B20-S0205/S00 |

|||||||||

| Color | Total thickness (mm) | Weight (kg/m2) | Top cover thickness (mm) | Top Coating Shore A | Working Temp. (°C) | Pull for 1% Elongation (N/mm) | Min. Pulley Dia.(mm) | Max. Width(mm) | Lateral Stability |

| B | 2 | 2.3 | 0.5 | 80 | -15/+80 | 8 | 40 | 3000 | * |

| C22-B25-S0207/S00D |

|||||||||

| Color | Total thickness (mm) | Weight (kg/m2) | Top cover thickness (mm) | Top Coating Shore A | Working Temp. (°C) | Pull for 1% Elongation (N/mm) | Min. Pulley Dia.(mm) | Max. Width(mm) | Lateral Stability |

| B | 2.5 | 2.7 | 0.7 | 80 | -10/+80 | 8 | 25 | 3000 | * |

| C25-B21-S0506/S00A |

|||||||||

| Color | Total thickness (mm) | Weight (kg/m2) | Top cover thickness (mm) | Top Coating Shore A | Working Temp. (°C) | Pull for 1% Elongation (N/mm) | Min. Pulley Dia.(mm) | Max. Width(mm) | Lateral Stability |

| B | 2.1 | 2.2 | 0.6 | 80 | -15/+80 | 8 | 40 | 3000 | * |

| C22-B55-S0435/S00D |

|||||||||

| Color | Total thickness (mm) | Weight (kg/m2) | Top cover thickness (mm) | Top Coating Shore A | Working Temp. (°C) | Pull for 1% Elongation (N/mm) | Min. Pulley Dia.(mm) | Max. Width(mm) | Lateral Stability |

| B | 5.5 | 4 | 3.5 | 55 | -20/+60 | 10 | 80 | 2000 | * |

Food Industry:

Light Duty Conveyor Belts for food industry are excellent resistant to oil and fat, non-toxic, healthy and easy to clean. The type of belts conforms with FDA, USDA and EU regulations, can be used in many applications in the following industries: bakery, confectionary, meat and poultry, fish, fruit and vegetables, dairy, agriculture etc.

The normal types are as follows:

| C25-BL20-S0105/S00O |

|||||||||

| Color | Total thickness (mm) | Weight (kg/m2) | Top cover thickness (mm) | Top Coating Shore A | Working Temp. (°C) | Pull for 1% Elongation (N/mm) | Min. Pulley Dia.(mm) | Max. Width(mm) | Lateral Stability |

| BL | 2 | 2.3 | 0.5 | 65 | -10/+90 | 10 | 25 | 3000 | * |

| C22-T18-S0000/S00O |

|||||||||

| Color | Total thickness (mm) | Weight (kg/m2) | Top cover thickness (mm) | Top Coating Shore A | Working Temp. (°C) | Pull for 1% Elongation (N/mm) | Min. Pulley Dia.(mm) | Max. Width(mm) | Lateral Stability |

| T | 1.8 | 1.7 | - | - | -10/+90 | 10 | 40 | 3000 | * |

| C25-W20-S0205/S00O |

|||||||||

| Color | Total thickness (mm) | Weight (kg/m2) | Top cover thickness (mm) | Top Coating Shore A | Working Temp. (°C) | Pull for 1% Elongation (N/mm) | Min. Pulley Dia.(mm) | Max. Width(mm) | Lateral Stability |

| W | 2 | 2.3 | 0.5 | 65 | -10/+90 | 10 | 25 | 3000 | * |

| C25-W30-S0110/S00O |

|||||||||

| Color | Total thickness (mm) | Weight (kg/m2) | Top cover thickness (mm) | Top Coating Shore A | Working Temp. (°C) | Pull for 1% Elongation (N/mm) | Min. Pulley Dia.(mm) | Max. Width(mm) | Lateral Stability |

| W | 3 | 3.3 | 1 | 65 | -10/+90 | 10 | 60 | 3000 | * |

| C22-W31-S0106/S05O |

|||||||||

| Color | Total thickness (mm) | Weight (kg/m2) | Top cover thickness (mm) | Top Coating Shore A | Working Temp. (°C) | Pull for 1% Elongation (N/mm) | Min. Pulley Dia.(mm) | Max. Width(mm) | Lateral Stability |

| W | 3.1 | 3.1 | 0.6 | 65 | -10/+90 | 10 | 50 | 3000 | * |

| U2-W14-S0103/S00 |

|||||||||

| Color | Total thickness (mm) | Weight (kg/m2) | Top cover thickness (mm) | Top Coating Shore A | Working Temp. (°C) | Pull for 1% Elongation (N/mm) | Min. Pulley Dia.(mm) | Max. Width(mm) | Lateral Stability |

| W | 1.4 | 1.3 | 0.3 | 86 | -20/+80 | 14 | 6 | 2700 | * |

Tobacco Industry:

Light Duty Conveyor Belts for tobacco industry are chemical resistant, abrasion resistant, have good performance at both high and low temperatures. The type of belts conforms with FDA, USDA and EU regulations, widely used in tobacco industry, from the tobacco harvest to the finished cigarette, and fulfill the tobacco industries regulations for pyrolysis.

The normal types are as follows:

| C12-T10-S0105/S00A |

|||||||||

| Color | Total thickness (mm) | Weight (kg/m2) | Top cover thickness (mm) | Top Coating Shore A | Working Temp. (°C) | Pull for 1% Elongation (N/mm) | Min. Pulley Dia.(mm) | Max. Width(mm) | Lateral Stability |

| T | 1 | 1.1 | 0.5 | 80 | -15/+80 | 5 | 10 | 3000 | * |

| C22-T13-S0000/S00 |

|||||||||

| Color | Total thickness (mm) | Weight (kg/m2) | Top cover thickness (mm) | Top Coating Shore A | Working Temp. (°C) | Pull for 1% Elongation (N/mm) | Min. Pulley Dia.(mm) | Max. Width(mm) | Lateral Stability |

| T | 1.3 | 1.2 | - | - | -15/+80 | 10 | 30 | 3000 | * |

| C25-T30-S0110/S00 |

|||||||||

| Color | Total thickness (mm) | Weight (kg/m2) | Top cover thickness (mm) | Top Coating Shore A | Working Temp. (°C) | Pull for 1% Elongation (N/mm) | Min. Pulley Dia.(mm) | Max. Width(mm) | Lateral Stability |

| T | 3 | 3.3 | 1 | 80 | -15/+80 | 8 | 60 | 3000 | * |

| C22-T56-S1035/S00 |

|||||||||

| Color | Total thickness (mm) | Weight (kg/m2) | Top cover thickness (mm) | Top Coating Shore A | Working Temp. (°C) | Pull for 1% Elongation (N/mm) | Min. Pulley Dia.(mm) | Max. Width(mm) | Lateral Stability |

| T | 5.6 | 3.3 | 3.5 | 70 | -15/+80 | 10 | 80 | 1500 | * |

| C22-T54-S1435/S00 |

|||||||||

| Color | Total thickness (mm) | Weight (kg/m2) | Top cover thickness (mm) | Top Coating Shore A | Working Temp. (°C) | Pull for 1% Elongation (N/mm) | Min. Pulley Dia.(mm) | Max. Width(mm) | Lateral Stability |

| T | 5.4 | 3.3 | 3.5 | 70 | -15/+80 | 10 | 80 | 3000 | * |

| C22-T48-S1528/S00 |

|||||||||

| Color | Total thickness (mm) | Weight (kg/m2) | Top cover thickness (mm) | Top Coating Shore A | Working Temp. (°C) | Pull for 1% Elongation (N/mm) | Min. Pulley Dia.(mm) | Max. Width(mm) | Lateral Stability |

| T | 4.8 | 4 | 2.8 | 55 | -20/+60 | 10 | 60 | 1500 | * |

| C22-T48-S2528/S00 |

|||||||||

| Color | Total thickness (mm) | Weight (kg/m2) | Top cover thickness (mm) | Top Coating Shore A | Working Temp. (°C) | Pull for 1% Elongation (N/mm) | Min. Pulley Dia.(mm) | Max. Width(mm) | Lateral Stability |

| T | 4.8 | 4 | 2.8 | 55 | -20/+60 | 10 | 60 | 1500 | * |

| E20-T30-S0110/S00 |

|||||||||

| Color | Total thickness (mm) | Weight (kg/m2) | Top cover thickness (mm) | Top Coating Shore A | Working Temp. (°C) | Pull for 1% Elongation (N/mm) | Min. Pulley Dia.(mm) | Max. Width(mm) | Lateral Stability |

| T | 3 | 2.6 | 1 | 90 | -10/+60 | 12 | 80 | 3000 | |

| E20-T56-S1435/S00 |

|||||||||

| Color | Total thickness (mm) | Weight (kg/m2) | Top cover thickness (mm) | Top Coating Shore A | Working Temp. (°C) | Pull for 1% Elongation (N/mm) | Min. Pulley Dia.(mm) | Max. Width(mm) | Lateral Stability |

| T | 5.6 | 3.2 | 3.5 | 90 | -10/+60 | 12 | 100 | 3000 | |

Other Industry:

We also supply Light Duty Conveyor Belt for other application, such as wood, marble and stone, textile, sports, automobile and tyre and so on.

The normal types are as follows:

| C22-P55-S0435/S00D |

|||||||||

| Color | Total thickness (mm) | Weight (kg/m2) | Top cover thickness (mm) | Top Coating Shore A | Working Temp. (°C) | Pull for 1% Elongation (N/mm) | Min. Pulley Dia.(mm) | Max. Width(mm) | Lateral Stability |

| P | 5.5 | 4 | 3.5 | 55 | -20/+60 | 10 | 80 | 2000 | * |

| C39-P58-S0120/S00 |

|||||||||

| Color | Total thickness (mm) | Weight (kg/m2) | Top cover thickness (mm) | Top Coating Shore A | Working Temp. (°C) | Pull for 1% Elongation (N/mm) | Min. Pulley Dia.(mm) | Max. Width(mm) | Lateral Stability |

| P | 5.8 | 6 | 2 | 74 | -15/+80 | 40 | 300 | 2800 | |

| C22-GR55-S1535/S00D |

|||||||||

| Color | Total thickness (mm) | Weight (kg/m2) | Top cover thickness (mm) | Top Coating Shore A | Working Temp. (°C) | Pull for 1% Elongation (N/mm) | Min. Pulley Dia.(mm) | Max. Width(mm) | Lateral Stability |

| GR | 5.5 | 5 | 3.5 | 55 | -20/+60 | 10 | 80 | 1500 | * |

| C32-B85-S0960/S00 |

|||||||||

| Color | Total thickness (mm) | Weight (kg/m2) | Top cover thickness (mm) | Top Coating Shore A | Working Temp. (°C) | Pull for 1% Elongation (N/mm) | Min. Pulley Dia.(mm) | Max. Width(mm) | Lateral Stability |

| B | 8.5 | 8.2 | 6 | 55 | -20/+60 | 15 | 120 | 2000 | * |

| C22-B75-S2655/S00D |

|||||||||

| Color | Total thickness (mm) | Weight (kg/m2) | Top cover thickness (mm) | Top Coating Shore A | Working Temp. (°C) | Pull for 1% Elongation (N/mm) | Min. Pulley Dia.(mm) | Max. Width(mm) | Lateral Stability |

| B | 7.5 | 5 | 5.5 | 55 | -20/+60 | 10 | 100 | 1500 | * |

| C39-P70-S0830/S00 |

|||||||||

| Color | Total thickness (mm) | Weight (kg/m2) | Top cover thickness (mm) | Top Coating Shore A | Working Temp. (°C) | Pull for 1% Elongation (N/mm) | Min. Pulley Dia.(mm) | Max. Width(mm) | Lateral Stability |

| P | 7 | 8.1 | 3 | 74 | -15/+80 | 50 | 350 | 2200 | |

| C49-P125-S0670/S00 |

|||||||||

| Color | Total thickness (mm) | Weight (kg/m2) | Top cover thickness (mm) | Top Coating Shore A | Working Temp. (°C) | Pull for 1% Elongation (N/mm) | Min. Pulley Dia.(mm) | Max. Width(mm) | Lateral Stability |

| P | 12.5 | 10.5 | 7 | 55 | -20/+60 | 70 | 450 | 2200 | |

| C49-P89-S0730/S00 |

|||||||||

| Color | Total thickness (mm) | Weight (kg/m2) | Top cover thickness (mm) | Top Coating Shore A | Working Temp. (°C) | Pull for 1% Elongation (N/mm) | Min. Pulley Dia.(mm) | Max. Width(mm) | Lateral Stability |

| P | 8.9 | 10.3 | 3 | 74 | -15/+80 | 70 | 450 | 2200 | |

![]()

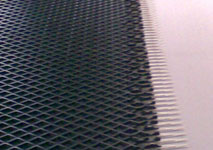

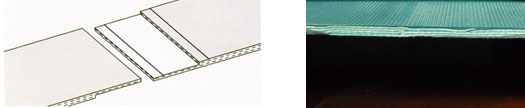

V. Joint Methods:

Z splice(finger joining)

This type is the most common method.

| Single finger joint | Double finger joint |

|

|

|

|

|

|

Over lap joint

This method is used mainly at marble conveyor belt, especially multi-plies belt types.

Fastener Method

Hook fastener and clamp fastener are available for this joint method.