Special Belts

Fabric impression belt

Mini Rough top belt:

![]()

Slight impression:

- one-sided impression

- two-sided impression

- width range: 1200-2000mm

Endless belt

Description:

Endless conveyor belt is conveyor belt that has been made into endless without joint in the process of production.

Characteristics:

- Its feature is that there is no joint in belt carcass, and the belt shall not be shortened in service life due to early failure in the joints of the belt. The belt is flat in surface and even in tension, thus it runs smoothly and its elongation in working is low.

- Cover Rubber classification: General, oil, heat and chemical-resistant, etc.

- We can make endless belt of light conveyor belt, general use belt and heavy duty belt according to customers' requirement.

Application:

It is widely used in building, mines, chemical plants, metallurgical industry and agriculture.

Sidewall conveyor belt

Description:

Sidewall conveyor belt can be used for horizontal, sloping or vertical conveyance, it is one of the most effective ways of elevating materials in a confined space, the economy is achieved by single belt operation, wide range material can be handled, less space and requirement, no transfer point, low maintenance and big capacity.

It is based on the following main components:

- Cross-Stabilized Base Belts

- Sidewalls

- Cleats

Click here to download this spreadsheet (PDF, 332KB)

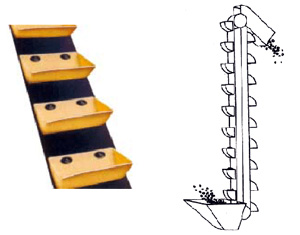

Elevator Conveyor Belting

Elevator conveyor belts:

The belt is made of either anti-tearing EP canvas or steel cord as center material with anti-tearing rubber cover, good application capability, running steadily, low maintenance.

Construction:

Rubber belt & elevator bucket.

Characteristics:

Little earth coverage, no pollution, great conveying capacity, suitable for conveying bulk material.

Application:

Vertical transportation of loose powdery material, widely used in building, mining, chemical, light industry, power station and grain etc. field.

Power Specifications of the rubber belt:

Carcass: EP or Cotton Duck

Max. Belt Width: ~2200 mm

Cover Rubber: Resistant to wear, oil, heat and anti-static.

Type Ply Cover Thickness (mm) EP100/EP125/ EP150/EP200/ 2-6 0.2+0.2;0.5+0.5;0.8+0.8;1+1;1.5+1.5;2+2

![]()

Elevator Buckets:

Power offers the most complete range in plastic elevator buckets. All types are available in HDPE or Nylon. Special buckets for minerals in extra heavy duties, centrifugal or gravity discharging.

- Deep Bottom Bucket

- Shallow Bottom Bucket

- Bottomless Bucket

- Split Bucket

- Rice Milling Bucket

- European Style Bucket

- Inductive Bucket

![]()

Elevator Bucket Bolts:

Elevator buckets are fitted to belts by means of specially designed bolts. The type of bolt used depends on the design of the back wall of the bucket and the shape of the holes in the bucket.

Pipe Belting

Description:

- Primarily used where bulk materials must be conveyed along horizontal and vertical curves in confined spaces, and/or where the environment has to be protected resp. where spillage must be avoided.

- The belt can negotiate tight horizontal and vertical curves. This eliminates or reduces transfer points, which is a big cost saving. Inclinations of up to 35° can be dealt with.

The belt must not flag so that the edge touches the conveyed material and it must not be too stiff, which would increase motor power resp. energy consumption and lead to premature wear of the belt and the idlers.

The belt must always open and never overlap on the pulleys.

The rubber covers must have enhanced specific properties that cope with the high stretch and with the effects of ozone and ultraviolet radiation.