Introduction:

StandardA pulleys use highest quality materials in a production process with advanced technology.

Our Quality Assurance system certified to ISO 9001:2000, lead our high quality products have reliable, long life performance in the field and appreciably reducing maintenance cost.

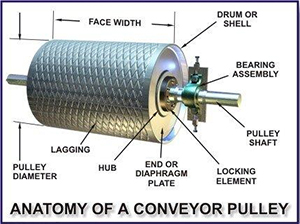

Each StandardA conveyor pulley is individually computer designed to meet the client's requirements. Design is based on the predetermined tolerances of stress loading and the distribution of load through the individual components of the conveyor pulley, within the critical calculation of fatigue factors.

Bending and shear stresses are limited in the design of drive and non-drive shafts together with the deflection of the shaft at the conveyor pulley disc.

Application:

Change the direction of the belt in a conveyor system, to drive the belt and to tension the belt.

Features:

- Special design to efficient avoid stress concentration, thermal concentration and prevent corrosion by impurity, water and air etc.

- Various welding and polishing method to improve working life and reduce enegry waste, noise.

- Working life: 40,000 - 50,000 hours.

Pulley type ranges:

We can offer:

- Drive pulley

- Tail pulley

- Snub pulley

- Bend pulley

- Take up pulley

- Wing pulley

- Motorized pulley

Surface:

Herringbone, diamond, ceramic lagging are available. Smooth and coated surface are also in list. For some special suface pattern, we can open mold as per customer requirement

Specification:

| Belt Width (mm) | Face Width (mm) | Pulley Diameter (mm) |

| 300 | 400 | 200, 250, 315, 400 |

| 400 | 500 | 200, 250, 315, 400, 500 |

| 500 | 600 | |

| 650 | 750 | 200, 250, 315, 400, 500, 630 |

| 800 | 950 | 200, 250, 315, 400, 500, 630, 800,1000, 1250, 1400 |

| 1000 | 1150 | |

| 1200 | 1400 | |

| 1400 | 1600 | |

| 1600 | 1800 | 200, 250, 315, 400, 500, 630, 800, 1000, 1250, 1400, 1600 |

| 1800 | 2000 | |

| 2000 | 2200 | 500, 630, 800,1000, 1250, 1400, 1600, 1800 |

| 2200 | 2500 | |

| 2400 | 2800 | |

| 2600 | 3000 | 800,1000, 1250, 1400, 1600, 1800 |

| 2800 | 3200 |